The course of conversion vehicles LPG / CNG

How does the complete rebuilding of the vehicle and what you need her?

First, it is necessary to contact us and arrange, if it is possible to rebuild your vehicle or not, and arrange in what price

session with the reconstruction will move.

To do this, you can use our inquiry form or contact us by mail or phone technik@autogascentrum.cz +420 383 324 912, +420 606 659 530. Here you can find all contacts.

The price is always determined in dependence on the model of your vehicle, injection (direct or sequential fuel injection) engine capacity and the number of engine cylinders. His role is also played by the vehicle manufacturer when some brands and types of vehicles is necessary to use any of the systems to protect the valves. Here you can find our complete price list. !!!!! Out for phony companies that do not PRICES ON THEIR WEBSITE !!!!!

How long does the conversion?

Because the vehicle is now an important part of life for every motorist trying to maintaining high quality of the work done to reconstruct the shortest possible time. Therefore assembly is conducted by two mechanics at the same time (one performs installation of the tank and the other assembly components in the engine compartment). In a conventional four-cylinder engine rebuilding takes one working day. Time-consuming reconstruction techniques you communicate with mounting demand. We can also arrange for rebuilding rent a replacement vehicle, where you only pay for the gas that pass. Renting a car is required to report in advance to have it ready for you.

What documents with them for rebuilding?

Conversion with you need:

- Large technical certificate – the license must sign that your car has been converted to LPG

- Small technical certificate, green card – after reconstruction is necessary to adjust the car in all operating modes in real traffic on the road. Therefore, it is necessary that the documents were in the vehicle from the vehicle for inspection Police.

Receiving a vehicle for rebuilding

Before starting the LPG conversion mechanics inspect your vehicle, focusing on the state of the fuel and ignition systems. LPG equipment most suitable choice after consultation with the customer in particular with respect to the use of the vehicle. Furthermore, the customer arranges type and size of the reservoir, the location of the filler neck and the location of the switch. Based on this information, we set a fixed final price.

Reconstruction

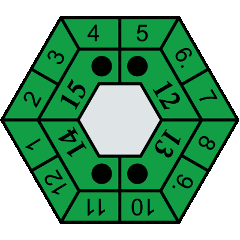

With LPG rebuilding begin simultaneously from both sides. One assembler is responsible for installing so-called. "Ancestor", ie. installation of the gearbox control unit injectors cut, installation of gas injectors and wiring. Second assembler installs LPG tank, filling connection, install the gas supply pipe, multivalves and switch.

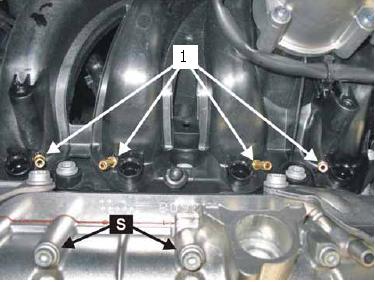

In the first step technician installs the injection nozzle (1). Through these nozzles, the gas is fed to the suction pipe and subsequently fed into the engine.

LPG injectors (2) are tubes connected to the injection nozzle (1). During their opening and the size of the dose control unit controls the fuel LPG depending on engine load.

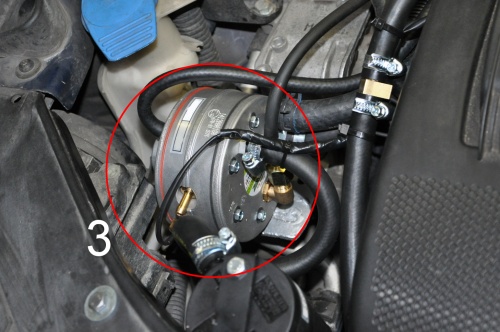

In the next step, the installation of the reducer (3) and safety valve for LPG gas. Reducer after heating to the appropriate temperature (about 40 ° C) converts the liquid phase LPG gas phase, which is fed through the injector into the engine.

Between the reducer and the injector is placed so. LPG gas phase filter (4). This filter collects debris from lower-grade gas injectors and protects against potential damage. The recommended interval for replacement of the filter is 20,000 km.

LPG system still contains so called. Filter the liquid phase, which is between the tank and the reducer (usually located at the reducer along with elektormagnetickým valve). Recommended interval for replacement of the filter is 40,000 km.

After the installation of pipes and hoses to supply LPG followed by the installation of electrical equipment.

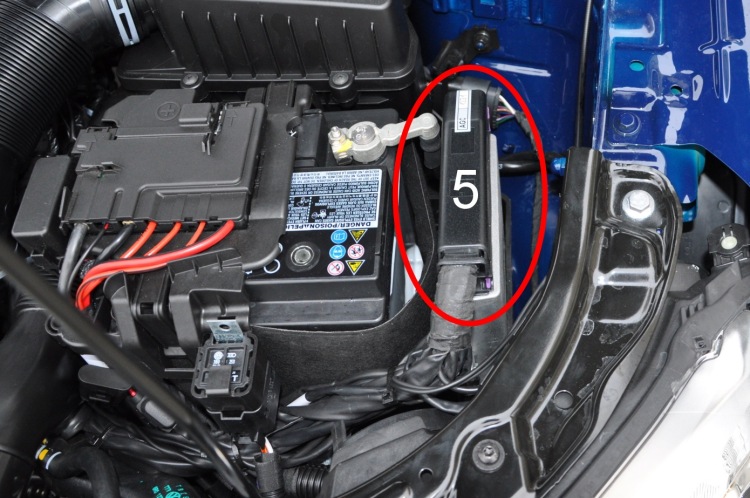

Fix LPG control unit (ECU) (5) - in most cases the unit is mounted as close to the battery as it is powered. The unit manages all operations carried out by the LPG system.

Switch (6) install by the customer at the place where it is in terms of the structure of the vehicle assembly feasible..

In the rear, meanwhile, is being installed LPG tank (7) and multivalves (8)

LPG tanks are divided into:

- Toroid – give instead of a spare wheel, so that the LPG tank took as little luggage space in the vehicle and if the vehicle has a margin beneath the vehicle, placed outside the toroidal tank under the vehicle.

- Cylindrical – give it where it can not be used toroidal tank or to the customer when the majority of demand for larger capacity tanks.

Multiventil - has several functions. Allows filling the tank, a float LPG senses water level in the tank and after opening the solenoid valve distributes gas in the engine compartment.

It also runs the filler neck assembly (9), - filling neck can be mounted in two ways

- Bumper – most commonly used

- Under the cap – install, where it allows the technical performance of the vehicle.

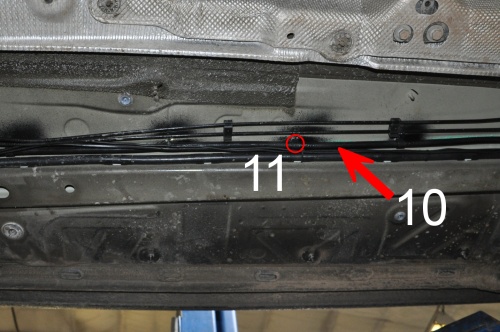

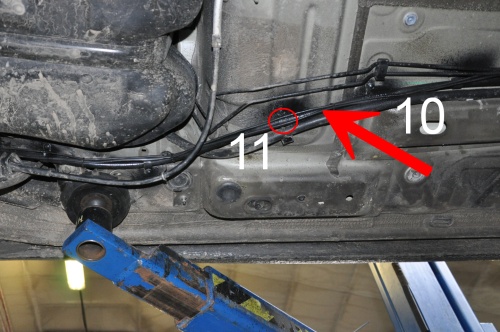

Copper pipe encased in black spaghetti insulation (10) (including utility cables measuring the level of gas), which leads from the multivalves LPG tanks to the front motor part is installed in accordance with applicable regulations and is laced with clips (11).

On some vehicles are susceptible to damage valves and valve seats is recommended to apply some of the ways valves.

The following options are available:

Blending of gasoline - unless the customer chooses this option, the system selects a control unit that has this feature.

Electronic (12) - fed by the program, which is dosed accurately and protection is more efficient and uses less additives. Here are the higher costs.

Vacuum (13) - dispenses depending on how fast you are going. Which is not as accurate as the electronic and has a greater consumption of additives. Acquisition costs are lower than for e-primase.

Installation is finished and will be the first refueling. Immediately after refueling, check all connections from the tank to the injectors LPG.

Use a computer to set basic parameters of the engine and perform automatic calibration. Subsequently, the gas adjustment maps by petrol maps in all modes of operation. Fitting end the diagnosis engine.

Delivery of the vehicle to the customer

Delivery of the vehicle to the customer:

- The first part of the handover will take place at the workshop, where the technician to the customer explaining the functions and operation of LPG equipment.

- The second part of the handover takes place in the office where the customer receives:

- Great vehicle registration document - with the added inscription of vehicle conversions to LPG.

- Service book - contains basic information about the LPG system and its operation, instructions for use and maintenance of LPG vehicles, warranty conditions, precautions when operating the vehicle with LPG, schedule service visits.

- Attachment to the great technical certificate - contains information about the device, which was installed in the vehicle. With this annex, along with great technical certificate purchaser must be relevant to the Department of Transport

- Certificate - A small card that contains information about revisions and major components LPG system. It serves as a document on the go

Payment

Payment Options:

Payment in cash

Credit card payment

![]()

Installment sales - find more information HERE

End

test

Obchodní zastoupení

.Contact

AUTOGAS - CENTRUM, spol. s r.o.

Heydukova 1269

386 01 Strakonice

IČ: 49018892

DIČ: CZ49018892

Mail: info@autogascentrum.cz

Telefon: +420 383 324 912

GSM: +420 606 659 530